Tin Plating (Tinning) Food Processing Equipment to Reduce Friction with a Sn Coating

Spraying Tin Anti-galling Coatings to Reduce Friction in a Screw Tread

A lead-screw, also known as a power screw or translation screw, is a screw used as a linkage in a machine, to translate turning motion into linear motion. Typical applications are linear actuators, machine slides (such as in machine tools), vises, presses, and jacks.

A tin coating provides superior lubrication, solderability and excellent corrosion resistance. Tin makes a superb anti-galling and anti-seizing wear surface. It also offers tarnish resistance.

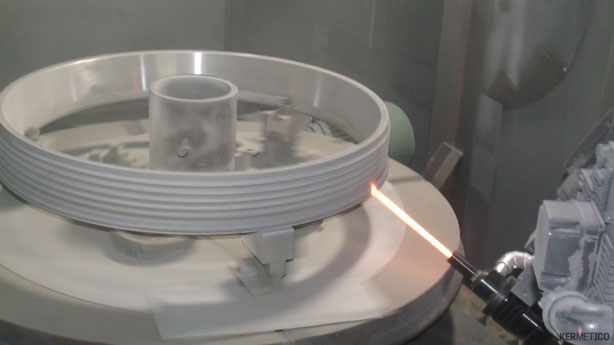

Kermetico HVAF Thermal Spray Tin Plating Equipment

The Kermetico High Velocity Air Fuel tinning for spraying Sn coatings onto mechanical parts of medical and food processing equipment to prevent galling on trapezoidal screw threads. HVAF Tin plating results in a uniform, high-bond, unoxidized layer of a Tin coating with perfect anti-frictional features. Less than an hour is needed to deposit a tin coating on the part shown below (1,000 mm (40”) OD).

Tinning is also used to protect parts from corrosion and to clad conductive layers onto polymer parts. The tin coatings are applied using the specialized Kermetico HVAF SL gun.

Blast and Spray with Kermetico High Velocity Equipment

We recommend spraying tin coatings using blast and spray operations. You can eliminate blasting and masking for blasting in a blast booth or cabinet. Just prepare a part for coating, blast it with the Kermetico HVAF gun (it is extremely fast and uniform) and spray with the same gun after switching the powder feed hose and perhaps changing the nozzle. The HVAF blasting is much faster and more accurate than conventional air blasting. Our customers and we have been successfully doing this with thousands of parts.

The HVAF Spray Tinning Process

The HVAF SL Gun sprays tin powder, heated and accelerated by the air-fuel gas combustion products. The mixture of compressed air and the chosen fuel gas flows into the combustion chamber through the orifices of a catalytic ceramic insert. The initial ignition of the mixture results in the heating of the insert above the mixtures’ auto-ignition temperature and then the hot insert continuously ignites the mixture. When entering the gun, the compressed air cools the chamber and the nozzle assembly. Then part of the preheated air is mixed with the chosen fuel gas and combusted. The spray powder is injected axially into a wide combustion chamber. The powder exiting the chamber is propelled into the nozzle of chosen length and configuration, where it is accelerated to a velocity that may be over 1,000 m/s. When impacting a substrate, the spray powder particles form a coating.

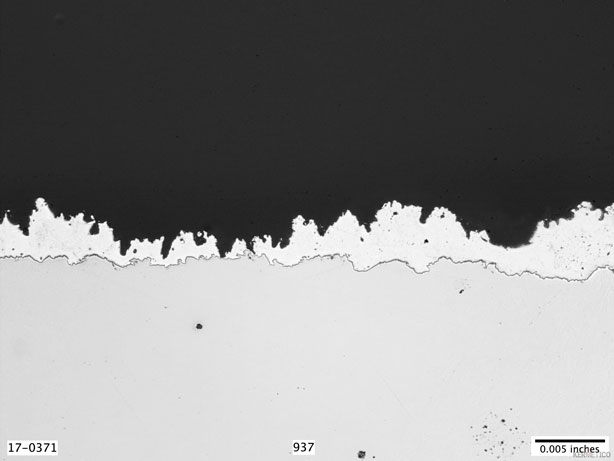

Kermetico HVAF Sprayed Tin Coating, 100x