Metal/Thermal spray coatings for food processing equipment provide excellent wear and corrosion resistance. Similar coatings are also used to provide wear and corrosion resistance to process pharmaceuticals and personnel hygiene products.

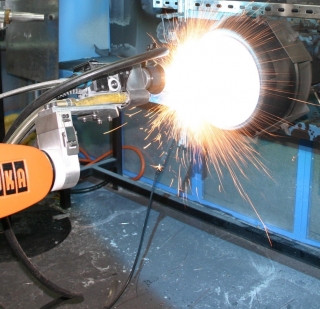

Induction pan being coated by robotically controlled Arc Spray system.

Tin Plating (Tinning) Food Processing Equipment to Reduce Friction with a Sn Coating

Spraying Tin Anti-galling Coatings to Reduce Friction in a Screw Tread

A lead-screw, also known as a power screw or translation screw, is a screw used as a linkage in a machine, to translate turning motion into linear motion. Typical applications are linear actuators, machine slides (such as in machine tools), vises, presses, and jacks.

A tin coating provides superior lubrication, solderability and excellent corrosion resistance. Tin makes a superb anti-galling and anti-seizing wear surface. It also offers tarnish resistance.

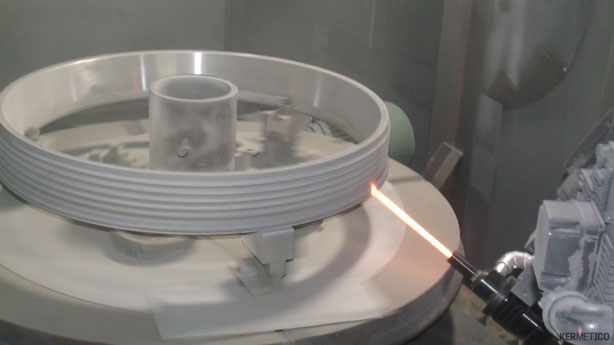

Kermetico HVAF Thermal Spray Tin Plating Equipment

The Kermetico High Velocity Air Fuel tinning for spraying Sn coatings onto mechanical parts of medical and food processing equipment to prevent galling on trapezoidal screw threads. HVAF Tin plating results in a uniform, high-bond, unoxidized layer of a Tin coating with perfect anti-frictional features. Less than an hour is needed to deposit a tin coating on the part shown below (1,000 mm (40”) OD).

Tinning is also used to protect parts from corrosion and to clad conductive layers onto polymer parts. The tin coatings are applied using the specialized Kermetico HVAF SL gun.

Blast and Spray with Kermetico High Velocity Equipment

We recommend spraying tin coatings using blast and spray operations. You can eliminate blasting and masking for blasting in a blast booth or cabinet. Just prepare a part for coating, blast it with the Kermetico HVAF gun (it is extremely fast and uniform) and spray with the same gun after switching the powder feed hose and perhaps changing the nozzle. The HVAF blasting is much faster and more accurate than conventional air blasting. Our customers and we have been successfully doing this with thousands of parts.

The HVAF Spray Tinning Process

The HVAF SL Gun sprays tin powder, heated and accelerated by the air-fuel gas combustion products. The mixture of compressed air and the chosen fuel gas flows into the combustion chamber through the orifices of a catalytic ceramic insert. The initial ignition of the mixture results in the heating of the insert above the mixtures’ auto-ignition temperature and then the hot insert continuously ignites the mixture. When entering the gun, the compressed air cools the chamber and the nozzle assembly. Then part of the preheated air is mixed with the chosen fuel gas and combusted. The spray powder is injected axially into a wide combustion chamber. The powder exiting the chamber is propelled into the nozzle of chosen length and configuration, where it is accelerated to a velocity that may be over 1,000 m/s. When impacting a substrate, the spray powder particles form a coating.

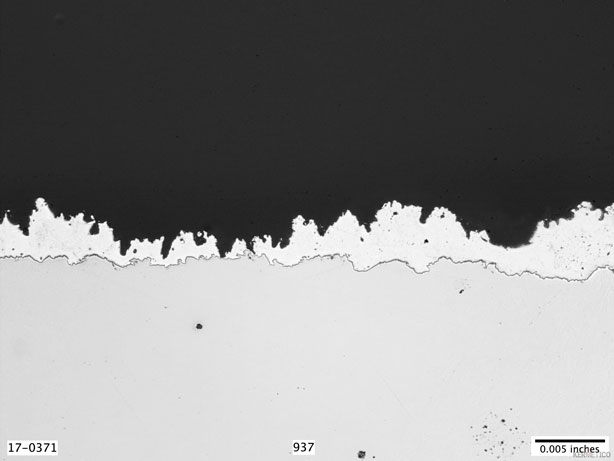

Kermetico HVAF Sprayed Tin Coating, 100x

Reinforced Stainless Steel Coating System for Cookware

Reason for use: The application of Arc sprayed Stainless Steel as a reinforced coating has been proven to drastically increase the working life of many types of cookware. By producing a thin Arc sprayed layer the fluoropolymer coating penetrates the sprayed surface. This produces high bond strengths and allows the high wear resistant Arc sprayed coating to protect the fluoropolymer coating.

Materials: Main Deposit: Stainless Steel or Titanium.

Arc Spray Process

In the Arc spray process, the raw material in the form of a pair of metallic wires, are melted by an electric arc. This molten material is atomised by a cone of compressed air and propelled towards the work piece. The molten spray solidifies on the component surface to form a dense, strongly adherent coating. Arc spray deposits possess a higher degree of bond strength than most other thermally sprayed deposits and the use of compressed air and electricity alone mean more economic coatings.

Method

Cleaning

The surface should be free from grease, oil or other contaminants as this would affect the adhesion of the sprayed coating.

Blasting

The surface should be grit blasted; the standard of surface cleanliness required is as Swedish Standard SA3. Surfaces not being treated should be masked before blasting.

Application of Sprayed Coating

Spraying should begin as soon as possible after preparation and before any visible sign of deterioration occurs. The surface speed should not be less than 18 metres/minute (60 feet per minute).

- The Arc Spray equipment should be set up in accordance with the MSSA manual for the spraying of St/St or Titanium wire.

- The area to be sprayed should be cleaned with a clean air blast to remove any loose particles of grit.

- The Arc Spray Pistol should be set so that the spray stream is at 90° to the surface being coated and traversed at an even speed giving a uniform coating.

- Apply St/St or Titanium Coating to the required thickness.

Spraying Parameters

Contact us for more information on particular spraying parameters.

General

There should be the minimum of interruption from commencement of preparation to completion of spraying. At all times, the prepared surface should be protected from dust, dirt, moisture etc.

Reinforced Ceramic Coating System for Cookware

Ceramic Coating

Reason for use: To reinforce fluoropolymer coating with a hard Ceramic coating. The application of Plasma sprayed ceramic powder 216 as a reinforced coating has been proven to increases the working life of many types of cookware. Even above that achieved by Arc sprayed Stainless Steel. By producing a thin Plasma sprayed layer the fluoropolymer coating penetrates the sprayed surface. This produces high bond strengths and allows the high wear resistant ceramic to protect the fluoropolymer coating (See Fig 1) from such items as cooking utensils.

Materials: Main Deposit: Ceramic Powder 216

Plasma Spray Process

Plasma is the term used to describe gas, which has been raised to such a high temperature that it ionises and becomes electrically conductive. In the case of Plasma Spraying, the Plasma is created by an electric arc burning within the nozzle of a plasma gun and the arc gas is formed into a plasma jet as it emerges from the nozzle. Powder particles are injected into this jet where they melt and then strike the surface at high velocity to produce a strongly adherent coating.

Method

Cleaning: The surface should be free from grease, oil or other contaminants as this would affect the adhesion of the sprayed coating.

Blasting: The surface should be grit blasted; the standard of surface cleanliness required is as Swedish Standard SA3. Surfaces not being treated should be masked before blasting.

Application of Sprayed Ceramic Coating

Spraying should begin as soon as possible after preparation and before any visible sign of deterioration occurs.

- The Plasma Equipment should be set up in accordance with the MSSA Manual for the spraying of St/St or Titanium wire.

- The area to be sprayed should be cleaned with a clean air blast to remove any loose particles of grit.

- The Plasma pistol should be set so that the spray stream is at 90° to the surface being coated and traversed at an even speed giving a uniform coating.

- Apply Ceramic coating to the required thickness.

- Spraying parameters for Ceramic Powder 216.

Note:

- Adjust secondary gas to achieve voltage.

- Adjust Rpm to achieve Powder Feed rate GPM.

- Air Jets at 80 psi parallel.

General

There should be the minimum of interruption from commencement of preparation to completion of spraying. At all times, the prepared surface should be protected from dust, dirt, moisture etc.

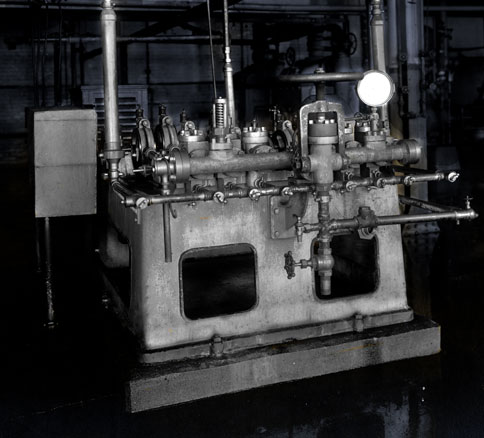

Mechanical Pumps

Food processing mechanical pump seals are made out of stainless steel - such as 316L SS and are coated with metal oxide ceramics such as Chrome Oxide and with Carbide containing materials for greatly enhanced wear resistance. Food processing pump shafts, sleeves and impellors can be coated for improved wear resistance. The coatings provide an excellent alternative to hard chrome plating.

Homogenizer Plungers

Homogenizer plungers used to homogenize products such as milk and juices are coated with carbide and oxide ceramic coatings for wear and corrosion protection.

For more information on Metal Spray equipment or consumables, call us on 07 3823 1004 or email us using our contact form.